StIves - Thermography Survey - 0800 043 8100

Our thermographic surveyors are fully approved and trained to UKTA Level 2 standards, verified to PCN level, and are BINDT certified.

What Is Thermal Imaging?

The thermographic device works in a similar way to a digital camera or recorder, taking pictures of the varying temperatures of an area with blue representing cold and red for the warmer surfaces. An insulated room should show up orange, indicating the warm air is remaining inside. If there's a gap in the insulation or a seal is broken then the warm air can escape - this area will be a more blue colour. It's reasons like this that make thermographic images such a powerful tool, helping save money and time by identifying issues early and showing exactly where they occur.

Why Have A Thermographic Survey?

A thermal survey is a non-intrusive method of finding air that's leaking from a room, uncovering thermal bridges or revealing gaps in insulation through thermal images that are clear to understand. To help pass Government regulations, these images will show the areas that require new sealing or where building development may need altering.

Unlike a traditional thermometer, the use of a camera offers the opportunity to scan larger areas at once while displaying any issues with pinpoint accuracy. The camera is therefore the most powerful tool for diagnosing building problems.

Invaluable to contractors and building owners alike, thermal imagery identifies issues with the building fabric without the need to strip back or knock down any unnecessary structures that would cost time and money when trying to get construction completed and up to code.

Thermal Imaging Reveals Heat Loss Areas

Cold drafts through a building or damp patches can be the result of poor or broken insulation and pipework. These can lead to further issues like mould or damp when left untreated resulting in costly maintenance work to set right. Condensation forms when warm air hits cold air so if there are any air leakage areas, it only takes the smallest of gaps, then huge complications can occur in the long run.

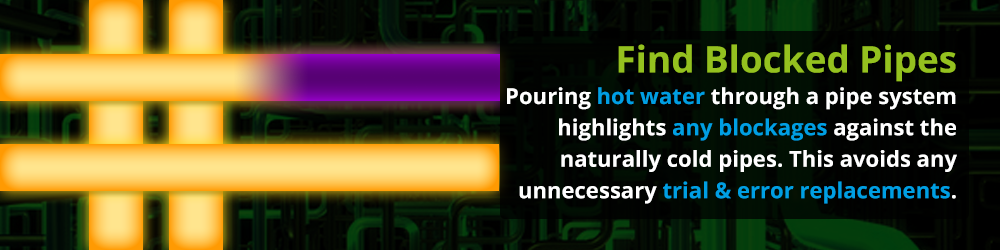

Pouring hot water through a pipe system will reveal any blockages with ease as to where the bright colour stops against the naturally cold pipes displayed in a darker tone. This avoids any trial and error replacement of pieces by giving you an exact position of the problem.

Following pipes, whether through a house or under city streets, thermal images can see if any steam or water is escaping leading to low pressure or damage to the surrounding areas. Mending these cracks and breakages will help solve issues in air conditioning, ventilation and central heating. These systems must maintain a certain temperature and humidity to ensure the air quality is of a decent enough standard around the building.

Moisture Detection Through Thermography

Thermographic surveys can detect damp patches while they are still hidden and therefore can be solved before any mould patches spread to more visible places. Damp patches take longer to change temperature and because of this, even if there doesn't appear to be any moisture build-up at first, our experienced thermal team knows how to reveal tougher areas by warming up a room first.

These types of damp areas provide a perfect breeding ground for mould and fungi that can cause some serious health issues. Condensation is the most common cause of moisture damage in buildings and can form almost anywhere - floors, walls, ceilings - and can take a long time to dry out as, generally speaking, most of the damage is beneath the surface.

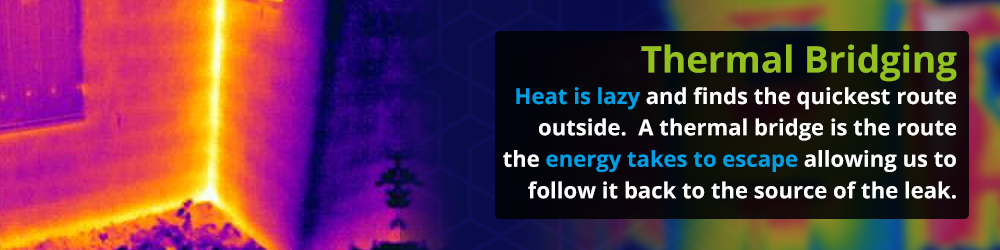

What's Meant By 'Thermal Bridging'?

A thermal bridge will highlight where energy is being wasted as heat is lazy and will follow the simplest path to the outside of a building. You can follow the heat's escape path to uncover the source of the leak and fix it, ultimately saving money on energy costs.

Further Benefits of A Thermal Survey

Though thermorgaphy is usually partnered with air quality, thermal imagary can reveal far more than that, for example, faulty electronics. Wire faults can cause overheating that would be undetectable by the naked eye from the outside until it's too late. Spotting these types of heat signatures early can avoid short-fusing a system and even fires around poorly managed units.

Thermography isn't simply used to show what's wrong with a building but how good too, such as if a wall or floor is completely dry upon completion. Doing this before completing the build or moving forward with construction helps create a solid foundation. If wet, however, there are certain techniques used to help the drying process and allow the building to be handed over to the client faster - with thermal images as proof of its condition.

Thermographic images highlight pipes and frameworks under the surface, showing if something's damaged or even where not to go during renovation or conversion. These structures are much clearer when behind plaster work and can indicate whether the plaster itself is wearing thin before cracks occur on the outside.

Building Regulations and Thermal Imagery

BREEAM and other sustainability statements as well as Part L under building regulations specifies that thermal surveys are now a requirement. With the proof a thermal image provides coupled with the accuracy and visual representation, this comes as little surprise. You're no longer just being told how a building has been constructed and how good the insulation and sealing is but being able to see easily and quickly makes a huge difference in not just the piece of mind for the owner but also as evidence for building regulators.